|

THE WORLD'S SMALLEST WATER BASIN |

EXHIBITS |

|||

|

EXHIBITS FRIENDS HERITAGE HOME LIME PARK OPEN DAYS PARKING TECHNOLOGY UNESCO |

||||

SUCCESS - Project director, Chris Close, after a day testing the SeaVax in an open air water basin. On this day in 2016, the 29th of July, the proof of concept model, cleaned microplastic from the test tank, collecting the litter in her hydro-cyclonic filters. The total cost of building the 2.23 meter (fully functional) model was around £120,000 pounds. Test tank costs, added to the project cost, but not prohibitively.

Not directly connected with the early electrical generating history of Herstmonceux Museum, though designed and built north of a 2nd World War bomb shelter just outside Lime Park, this facility is thought to be the world's smallest water test tank. It does not tow a model along a long thin tank. Instead, water is pumped in two channels, in re-circulating fashion, much as the closed loop wind tunnel, featured elsewhere on this site, also an exhibit at the Museum.

In the old days thought was given to streamlining the shape of airplanes, boat hulls and car bodies. But there was not much scientific measurement. If a new shape went faster than an earlier shape, that was good enough. The principle of drag and teardrop shapes to reduce drag was well enough understood from looking at fish and birds. But

thought of testing a shape before building a vehicle, to predict performance, was made a reality by the

Wright Brothers in 1903, though nobody would pay them for a

patent license in the USA, and Europe aided such

rejection in refusing to issue a patent to them at all. Of course, the

Wilbur and Orville were too far ahead of their time, for big money to

see a return for such investment. And that is the baseline in modern

society; can they make a profit, or stop someone else from taking their

custom.

In 1969, Ford debuted a fancy, first-of-its-kind intermittent windshield wiper on its line of Mercury cars.

A test model is loaded onto the gantry on the dry side of the sluice gate (seen in red), then moved along the overhead track, into position in the test tank, and lowered into the water basin.

This water test tank is a research tool developed to assist naval architects and fluid flow scientists, who were at the time studying the efficiency of a solar powered triple hull of an unusual design. The vessel was SeaVax, a ship designed to hoover up plastic from the ocean. This test tank had to serve a dual purpose, not only to measure hull drag in various sea states, but also to demonstrate the efficiency of a hydrocyclonic collector head, at removing plastic from the water.

The water basin is now useful to measure the hull drag of the Elizabeth Swann, a solar and hydrogen powered vessel that uses photovoltaic wings to harness energy from nature, much the same as the SeaVax. In this case, wind-age and roll of the vessel are many times more important in high winds, than in conventional vessels.

HOUSING - Turning the open air tank, into a closed, controlled environment. This is the roof and walls under construction.

One of the main factors affecting the speed, or energy consumption of a boat or ship, is the drag of the vessel. For the most part, this is determined by the shape of the vehicle's hull (monohull), or in the case of a multihull; hulls (catamaran or trimaran). How slippery a hullform is might mean a faster vessel, such as in yacht and powerboat racing events, or how much a boat will cost to run and sail.

One of the key features of the world's smallest water test tank, is the ability to empty the basin, while filtering any plastic that may have been introduced when measuring the effectiveness of the filtration head. The tank can then be re-filled in under 40 minutes with fresh water. Such that testing can continue with a different mix of simulated marine litter. After which the cycle can be repeated over and over again, with a 40 minute recharging time, instead of days pumping out or filtering of conventional tow test tanks.

Test models can be turned 90 degrees, or through any rotation angle, for testing side on the waves and wind. The fans can be adjusted to create a tropical revolving storm effect.

Water tanks and testing is hardly mainstream conversation, yet this highly specialized subject is also diverse, with each installation being virtually unique. For this reason

the developers took a look at some of the variations, because you can learn something from every one - otherwise, they would all be the same of course.

TWO TANKS - The round tank in a large underground water storage unit. The water basin is above ground. Water may be pumped to and from the two tanks, using two different pumps. When being pumped from the water basin to the subsurface storage tank, the water goes through a filter, to remove plastic particles. In use, the water basin has a circulating system, like most larger swimming pools. To keep the water clear. Reusing the water helps to conserve the planet.

FILTRATION - This is the circulating pump and filter system as installed. It proved to be quite effective in use.

TWIN PUMPS - It's a bit like two wind tunnels side by side. Matched flow rate pumps move the water, while the model stays still. The net effect is the same as towing the vessel along a tank, except that wave making has to be introduced just ahead of the vessel, to simulate operation in choppy seas. A mechanism to enable this was designed and tested for proof of concept, but not published or otherwise shown, to preserve the intellectual property. Control vanes are a feature, that are inserted into the test tank as required.

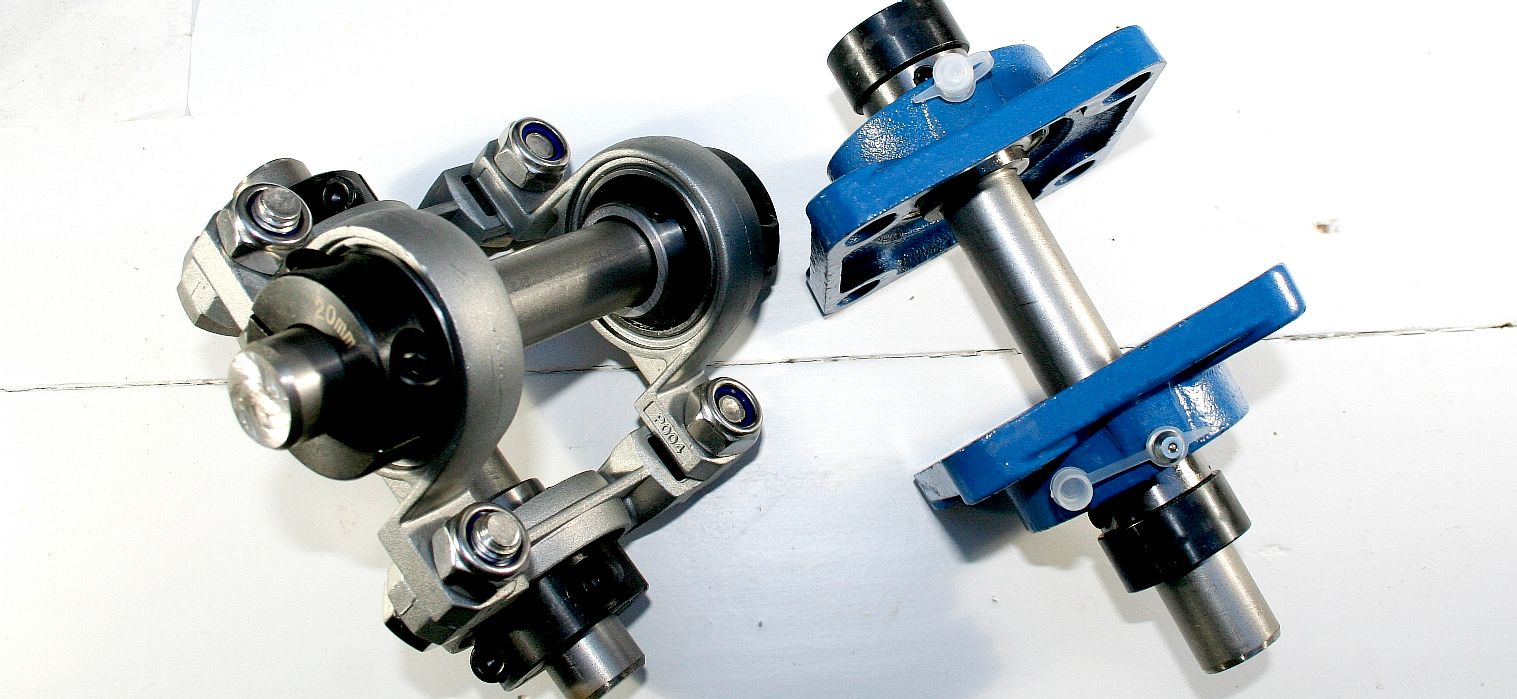

BEARINGS - The ball bearings and stainless steel shafts that went to form a six axis gimbal. Allowing a test model complete freedom of movements when encountering waves, fore-aft, side-to-side, and up and down.

A time lapse video of the test tank roof frames under construction.

BRICKS & MORTAR - CARRIAGE - DRAINAGE - FACILITIES - FILTRATION - GLASS & PAINT - GANTRY - GIMBALS - HATCHES HYDRODYNAMICS HISTORY - INSTRUMENTS - LABORATORY - LAMINATING - LOGISTICS - OUR TEST TANK - PROOFING - REVIEWS SCREEDING - SEAVAX TEST VIDEOS - SLUICE GATE - SLUICE MOTOR - SOLAR BATTERIES - WAVE MAKING - WINCH - WIND MACHINE

CURING THE LEAKS - The early experiments were marred by leaks through the flagstone joints. This was cured with a sharp sand, cement screed, sealed with several coats of epoxy paint. A rubber hose that sealed the sluice gate, where there was an annoying slight dribble of water on one of the timber joins, was replaced with a silicone tube, and the join filled flat. The result is a tank that holds water.

BLOW ME DOWN - One of the fan banks. They are now wired in permanently, with remote controls for each bank, to prevent electric shock.

THE GANTRY - Chris Close admires his work. He learned to weld on this project, helping to make the stainless steel track and the lifting and lowering mechanism.

Water

drag coefficient Cd is equal to the drag D divided by the quantity:

water density r times reference area A times one half of the velocity V squared.

This

formula only works to calculate smooth, or pipe drag. Not wave drag. Or,

the speed/length ratio of a hull.

RESTORATION - Presently the subject of a good clean, this is the wind tunnel exhibit in the Museum in September 2023. The model used in the design of the Bluebird Electric 1 and DC50 vehicles. Over the years, the paint on the aluminium tunnel has crazed, where it was coated in epoxy resin, and then matt black, and the expansion coefficients in winter and blazing summer heat are different. The machine is still operable. The fan unit was tested on the 21st, the power supply unit located shortly thereafter, which appeared to be giving variable voltage readings, thus potentially still operable after 30 years gathering dust.

TOW

TEST TANK HISTORY

There are several innovative vehicles and vessels on permanent display at Herstmonceux Museum, including:

1. Art Gallery - Collection of paintings, pictures, graphics, sculptures, wooden carvings & exotic glassware 2. Archives - Historic documents library, patents, trademarks, copyright, films, catalogued legal papers & letters 3. An Edwardian ice well, throwback to the days before refrigeration 4. A large underground (condensation/cooling) and water storage chamber for ice making 5. The world's smallest water basin, test tank for model boats & ships to 1:20 scale 6. World's smallest wind tunnel, vehicle drag measuring instrument using electronic strain-gauges 7. Three PV boat models, Navigator, SWATH & 2 cats + route map prior to Swiss PlanetSolar 8. Seavax, the ocean cleanup proof of concept prototype from 2016 9. AmphiMax, radio controlled (working) beach launching & recovery vehicle for SeaVax 10. Anthony the most dangerous giant Australian bulldog ant, 300 times normal size 11. EV - FCEV refueling station model in 1:20 scale 12. The only working (fully functional) water well in Herstmonceux village 13. The fountain of youth, supplied from natural well water drawn on site 14. Second World War, 'Anderson Inspired,' bomb proof shelter constructed by Major Charles de Roemer 15. City sports FCEV-BEV, hydrogen gull wing proof of concept DC50 electric car 16. Land speed record car: Bluebird-Electric BE1 (original 1st) with battery cartridge exchange 17. Land speed record car: Bluebird-Electric BE2 (original 2nd) with cartridge exchange 18. A complete mummified squirrel, found when re-roofing the Museum June 2017 19. A fully operational, and restored VW Kombi van dating from 1978 (historic vehicle) 20. BMW i3, battery electric vehicle hybrid, with onboard generator range extender 21. Solar panel, sun tracking system, with battery storage 22. A hornet's nest found on site & preserved in 2016 (reported as [Asian] invasive species, to be safe) 23. Three sewing machines, including an antique Singer and a Brother industrial. 24. Adventure climbing frames for children (back to nature) Swiss Family Robinson 25. 'Elizabeth Swann' proof of concept model 1:20 scale hydrogen powered trimaran 26. Holm oaks, planting and growing trees from acorns on site, re-wilding in Sussex

|

||||

|

|

||||

|

EXHIBITS FRIENDS HERITAGE HOME LIME PARK OPEN DAYS PARKING TECHNOLOGY UNESCO

Copyright © 2023 Lime Park Heritage Trust. A not for profit organisation with charitable objects.

|

||||